Digital Transformation in Supply Chain

4 years ago, the pandemic underscored the critical need for supply chain digitalization. The global lockdown caused a major disruption in the industry, which made market players to rethink their strategy. Businessmen around the globe wanted to achieve uninterrupted production, ordering and shipment levels regardless of unforeseen challenges. That’s why nowadays they keep on actively adopting advanced technologies. The IoT arrival has greatly affected how supply chains function on a strategic level. Enterprises keep on implementing embedded sensors, GPS, and RFID across their facilities. Many of them are migrating their systems to the cloud. Numbers also speak for themselves, and the most recent statistics proves the world understood the assignment, and early adopters are already enjoying the rewards that come with their wise investment decisions.

In this article, we explore the reasons why supply chain modernization is inevitable if you want to stay competitive in today’s market. Our objective is to demonstrate that change should not be viewed as something intimidating or frightening, but rather as an opportunity for excitement, fascination, and growth!

What is Supply Chain Digital Transformation?

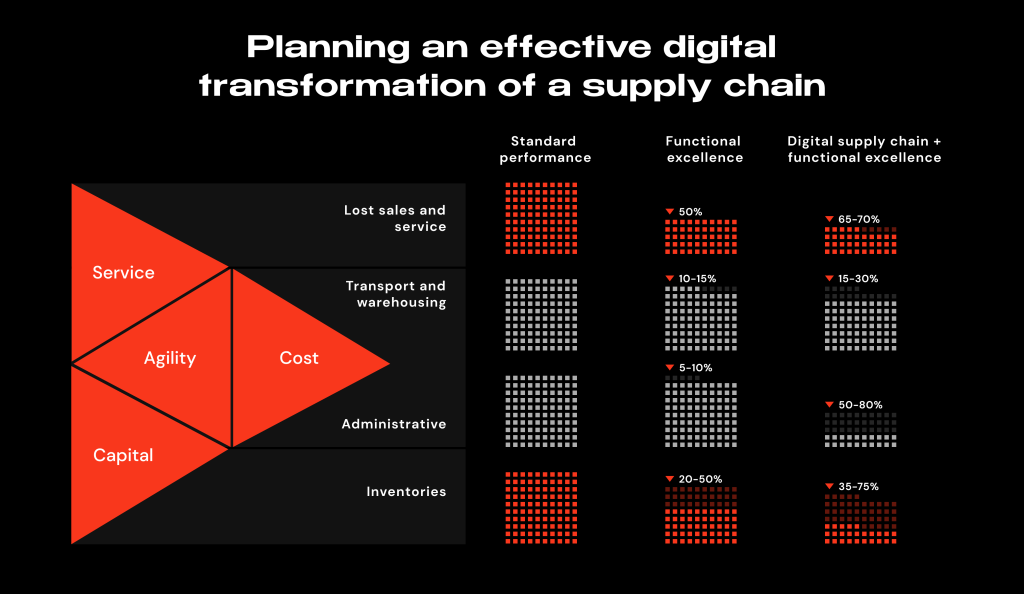

Let’s find out what exactly supply chain digital transformation means. Here, we speak about the process of utilizing various tools to modernize traditional SC management practices. The goal is to enhance operational efficiency, agility, transparency within the whole ecosystem. For instance, why should organizations invest in advanced analytics tools? The answer is pretty simple: workflow optimization and continuous improvement. They gain valuable insights into daily operations and identify inefficiencies based on actual facts. This transformation also enables proper end-to-end visibility i.e. item tracking from production to delivery. This approach lets manufacturers and involved parties keep a proper quality level.

However, numerous organizations still remain hesitant to embark on this journey. It may be due to their uncertainty about where to begin and what it truly entails. But the journey is not that scary. Let us prove this point!

How does it Work?

Let’s talk about traditional supply chains, and take a clothing retailer as an example. In this case, the retailer sources its products from various suppliers. These include fabric manufacturers, button makers, sewing factories. Initially, the retailer forecasts the demand for different types of clothing based on sales numbers and trends. Then, they place orders with suppliers for the required components, often by phone or e-mail. There is no interconnection between involved partners, so each party has to contact another one separately. Once the raw materials are received, they are transported to the manufacturing facilities. The finished items are packaged manually and sent to a central distribution center. There are no tracking devices so it is unclear what is the status of each item. Then, items are shipped in bulk to individual stores based on anticipated demand. Some of them get lost on the way. The deliveryman gets the remaining unsold items from the store back to the facility. It happened, because the demand was not calculated right. Customers did not need that much orange sweaters and velvet sweats, even if they are considered trendy.

As we see, in such scenarios, decision-making is often reactive. Predefined inflexible rules do not let the company adapt quickly to changing market dynamics. The linear structure means each stage is connected sequentially. This creates bottlenecks and delays. And, of course, the ecosystem relies heavily on manual intervention. Any changes or updates to orders or delivery schedules take time to communicate and may not always be in real-time. It increases chances of errors and delays.

But, what if the retailer decides to embrace digital innovations?

To begin, the retailer leverages real-time data and analytics to analyze customer buying patterns, social media trends, and market insights. The aim is to anticipate which clothing items will be in high demand. Then, the retailer connects with their network of suppliers through a digital platform. They place orders electronically, so suppliers receive all the details instantaneously. Suppliers also get access to updated inventory information and optimize their production schedules. Once the raw materials are received, sensors and RFID tags are attached to them. Tags provide visibility into each item’s location and status, reducing chances of errors.

Smart machines and robots assist in cutting, sewing, and finishing garments. ML algorithms identify bottlenecks and suggest improvements. All produced items get a separate RFID label containing product info/tracking details. This tagging enables seamless inventory management and tracking at every step. After the arrival to distribution centers, items are sorted and prepared for shipment based on current demand. Through a centralized platform, the retailer has complete visibility into current inventory levels, shipment statuses, and sales numbers across all their stores.

In this scenario, every move depends on real-time data and analytics. Decisions are made promptly, based on current indicators, not assumptions or approximate numbers. The stakeholders connect with each other through an interconnected network. Fast, reliable, efficient.

Why is a Digitized Supply Chain Effective?

Our example shows how the retailer managed to achieve increased visibility and transparency. It is the main advantage here, as it becomes a basis for cost-effectiveness and time savings. With modern digital tools, organizations track and monitor every aspect in real-time. This includes assets, inventory levels, production schedules, transportation logistics, and other touch points. Furthermore, the digitized supply chain generates vast amounts of data like sales figures or production metrics. Businesses can analyze this info and adapt their processes accordingly. Plus, repetitive tasks such as data entry, order processing or inventory management become automated. Employees invest their time in strategic planning and revenue generation. A win-win situation!

Technology used for Digitized Supply Chain

Internet of Things

IoT devices facilitate accurate and automated inventory tracking. By equipping products, packages, or even storage units with sensors, businesses can monitor their location, condition, and quantities. Other benefits:

1) IoT devices provide insights into factors like vehicle performance, route optimization, and maintenance requirements. Additionally, IoT-enabled warehousing solutions enhance accuracy and speed up picking and packing processes.

2) Using devices, companies monitor environmental conditions like temperature, humidity, and vibrations. It helps them detect issues that could impact product quality.

3) Sensors can monitor equipment and machinery in real-time. It means businesses can detect potential failures or malfunctions, avoiding costly repairs.

Artificial Intelligence

AI algorithms may analyze market trends to generate more accurate demand forecasts. By automating processes, optimizing routes, and predicting patterns, AI helps reduce operating costs associated with inventory management, transportation, and warehousing. Besides that, ML and RPA assist in automating repetitive tasks. AI-powered robots may handle warehouse operations, sorting, and picking. Algorithms may even evaluate supplier performance by analyzing delivery times, quality metrics, pricing. Based on the result, enterprises identify the most reliable and cost-effective suppliers.

Blockchain

Supply chains face numerous challenges, including lack of transparency and vulnerability to fraud. To address these issues, businesses are turning to the blockchain technology. Here, a distributed ledger records all transactions/interactions across the SC. This creates a transparent and immutable audit trail, enabling stakeholders to trace the journey of products from their origin to the end consumer. Such transparency helps identify inefficiencies, detect counterfeit goods, and ensure compliance with regulations. Blockchain’s cryptographic algorithms and decentralized structure make it highly secure. Each transaction recorded on the blockchain is verified by multiple participants. It eliminates the need for intermediaries and reduces the risk of fraudulent activities.

Cloud Computing

CC provides a centralized repository for storing and managing data. By moving to the cloud, businesses eliminate the need for multiple disparate systems and spreadsheets. Users securely access the platform from any device with an internet connection.

With cloud-based infrastructure, companies easily expand or downsize their operations without the need for significant infrastructure investments. You can also expect great protection against cyber threats: service providers usually implement advanced security protocols, encryption, backup mechanisms.

Businesses subscribe to cloud services on a pay-as-you-go basis instead of investing in hardware. This cost-effective approach allows them to allocate resources more efficiently. APIs for easy connectivity between various platforms like ERP or CRM provide headache-free integration options.

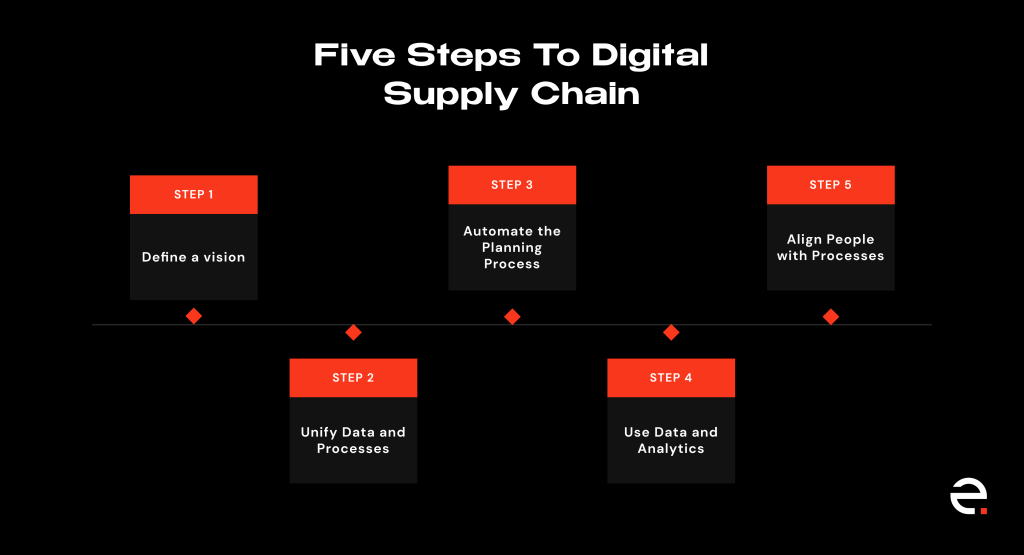

Important Steps in the Supply Chain Transformation Process

Embarking on a supply chain transformation journey requires careful planning and execution. Here are the most important steps to follow:

Assess Current State & Define Objectives

Conduct a comprehensive analysis of existing processes, systems, and capabilities. Identify areas of weakness and opportunities for improvement. Once the assessment is complete, define the objectives of the future changes. Set specific, measurable, achievable, relevant, and time-bound objectives.

Develop a Unified Strategy

A strategy outlines how you will achieve desired outcomes, necessary steps and resources. Remember, this transformation is a cross-functional endeavor. It requires the involvement of various stakeholders. Engage key individuals from different departments: procurement, logistics, IT, etc.

Such collaboration is vital for a smooth transition to new instruments/strategies.

Implement, Monitor and Evaluate

Start adopting chosen technologies. Note, this is an ongoing journey which requires constant monitoring and evaluation. You have to make sure desired outcomes are being achieved. Establish KPIs and regularly measure progress against these metrics.

Supply Chain Digitalization as an Important Part of Business Digitalization

Struggling to keep up with the rapidly evolving digital landscape? Ein-des-ein is here to revolutionize your supply chain through seamless digitalization! Don’t let outdated software and practices hold you back any longer. Contact us today for a consultation on supply chain digitization!

FAQ

-

What is digital transformation in supply chain?

- Digital transformation in supply chain refers to the integration of modern tools/strategies to fundamentally streamline the flow of goods and services from the sourcing of raw materials to the delivery of finished products.

-

How to coordinate digital goods in a supply chain process?

- Identify the “goods” to include in the SC, such as programs or media files. Next, establish a clear system for managing them. Use specialized software or cloud-based instruments for that. Remember, these programs or files should be properly protected. Regular backups and encryption methods assist in safeguarding these assets.

-

Has your company ever integrated the mentioned technologies into applications from other industries?

-

Absolutely! We work with a range of industries, including healthcare, education, logistics, farming, construction and more! For example, a year ago we developed an AI-powered application for a healthcare facility. Here, we implemented an intelligent diagnostic module. It utilized ML algorithms to analyze medical data and assist doctors in making accurate diagnoses. This feature aimed to enhance diagnostic accuracy and improve treatment outcomes. Besides that, we implemented a secure electronic health records (EHR) management feature. It enabled physicians to access and update patient info:

- medical history

- test results

- treatment plans.

We also included an appointment scheduling feature. It allowed patients to book appointments with doctors conveniently through the app. This feature aimed to streamline the scheduling process and reduce administrative overhead for the facility. We also included a health education feature. It offered access to a library of educational resources, including articles, videos, and infographics, to promote health literacy among patients. This feature aimed to empower patients with knowledge for better self-care and prevention of illnesses.

EDE team also worked on a Blockchain-based crypto wallet development. We implemented a decentralized architecture to ensure the safety of users’ assets. This allowed for secure storage and transfer of cryptocurrencies. Next, we integrated multi-currency support. Users could store and manage various cryptocurrencies in a single wallet. This feature provided convenience and flexibility for people who held multiple types of digital assets. To enhance user experience, we incorporated a user-friendly interface with intuitive navigation.

In order to provide transparency and accountability, we integrated a transaction history feature. Users could view their transaction details, including incoming and outgoing transfers. A seamless integration with popular decentralized exchanges allowed users to easily buy, sell, and trade cryptocurrencies within the wallet itself. Additionally, we implemented two-factor authentication. This feature added an extra layer of protection by requiring users to verify their identity through a secondary device or method.

EDE also successfully built a cloud-based e-commerce platform. We implemented scalable infrastructure and reliable cloud hosting to ensure high performance. A user-friendly interface with intuitive navigation let customers easily browse products, add them to their cart, and proceed to checkout. An address auto-complete feature minimized manual input errors, saving time for customers. With a robust product catalog feature, merchants could easily add, edit, and organize offered products. In order to facilitate secure transactions, we implemented a secure payment gateway. Customers could make payments using various payment methods. Moreover, we integrated a personalized recommendation engine. It analyzed customer behavior and provided tailored product recommendations. This ultimately increased cross-selling and upselling numbers. Here, we also implemented a client review and rating system. Customers were able to provide feedback and share their experiences.